WE GIVE SHAPE TO YOUR PROJECTS

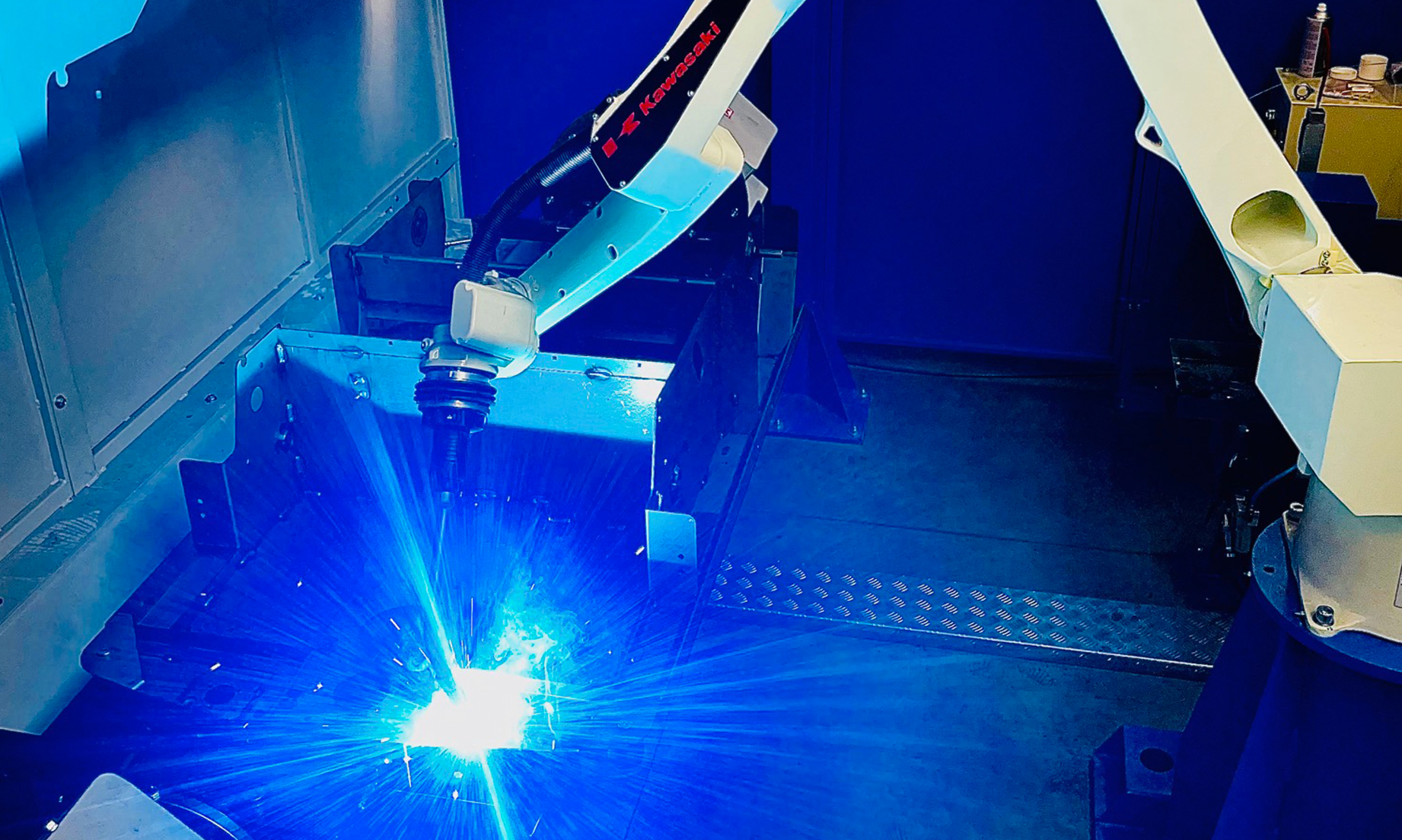

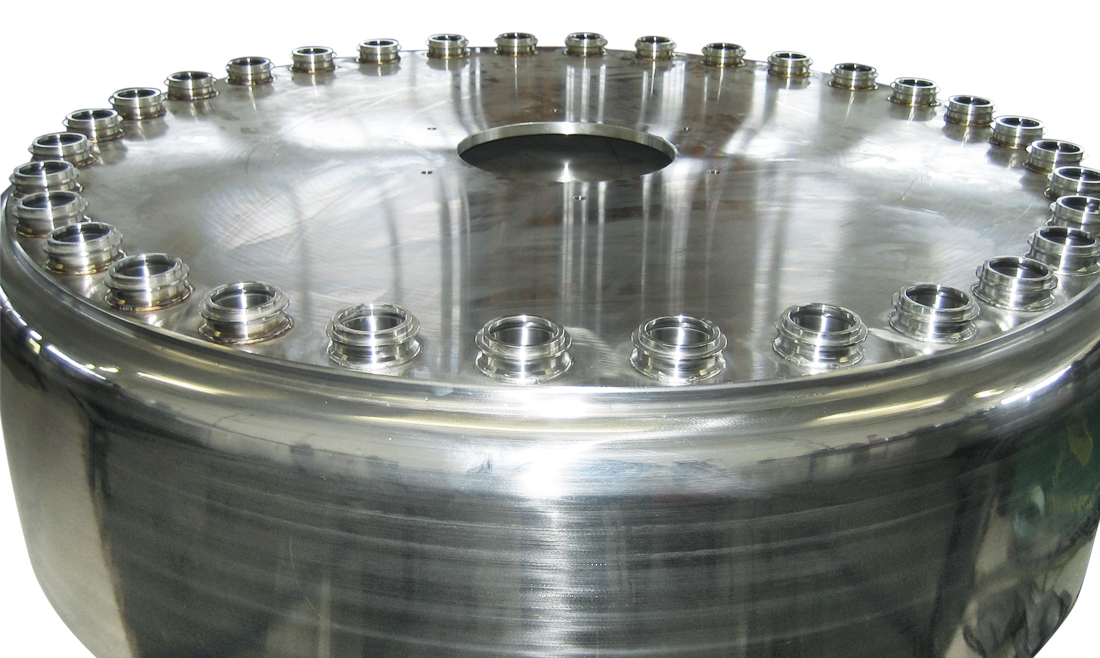

At Newsald we have been operating in the metal processing sector for twenty years, specialising in robotic welding of steel and aluminium and in process to restore the original surface finish.

CONSULTING

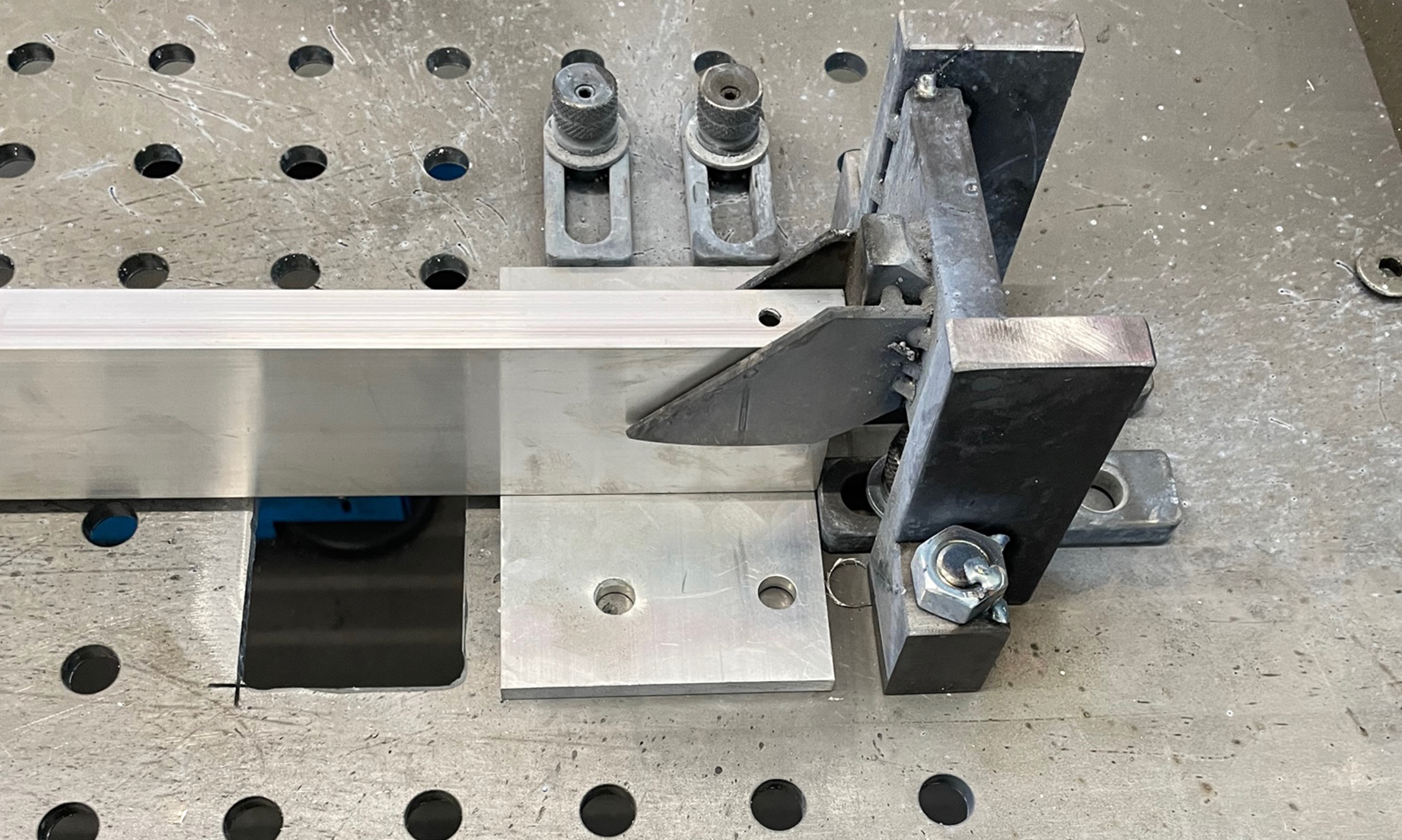

We manage your project right from the initial design up to its industrialisation, so as to be sure to best meet your needs.

PROTOTYPING

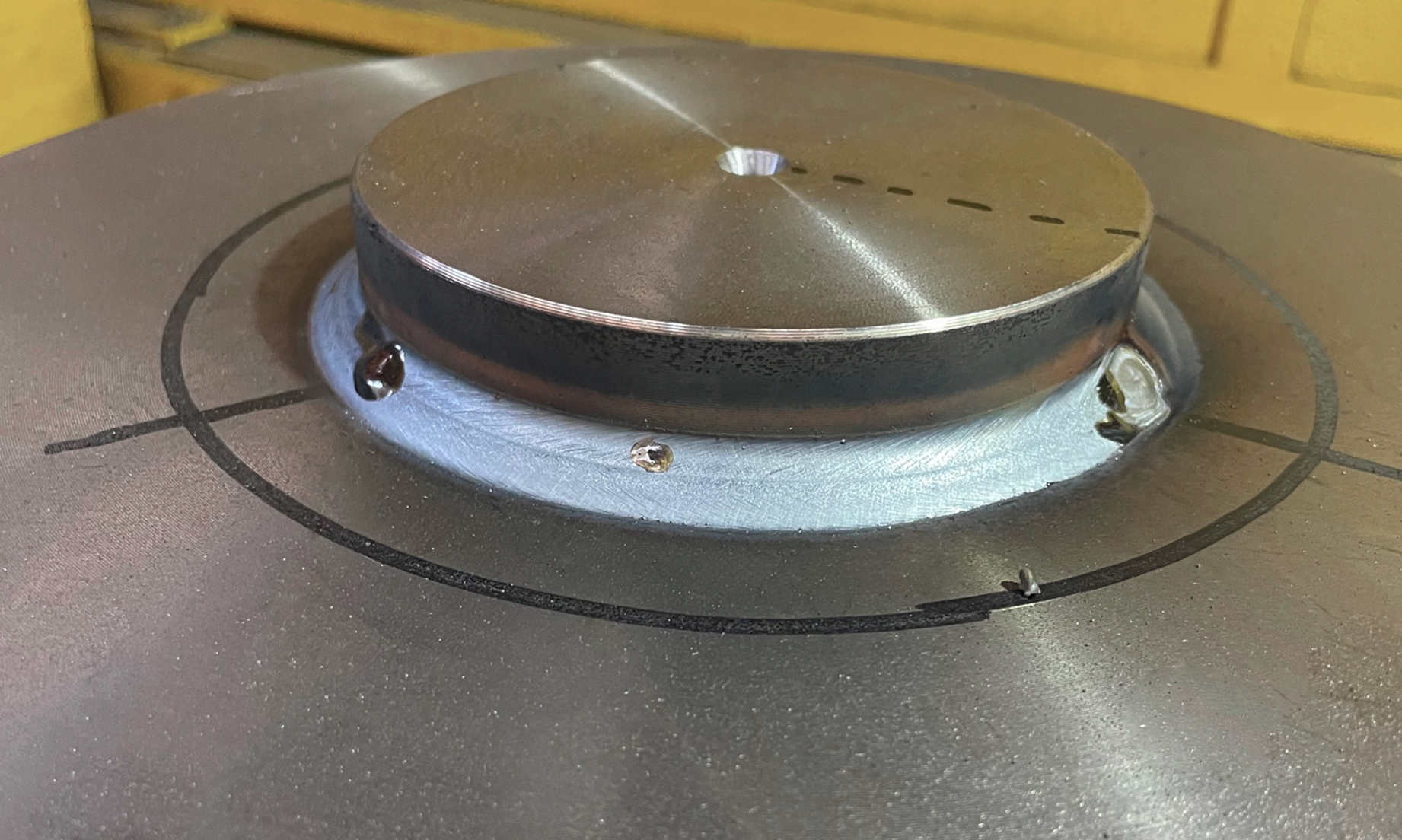

The production of prototypes means we can check that the final piece is correct before starting production.

CUSTOMISATION

Special processes to meet the specific needs of new projects is one of our main strengths.

ASSEMBLY

We can assist you in the demanding work to assemble the components we make, even adding in parts made by other suppliers.

WE CONTINUALLY SEARCH FOR INNOVATIVE SOLUTIONS TO INVEST IN SO AS TO IMPROVE AND DIGITISE OUR PRODUCTION PROCESS. THIS FOCUS, TOGETHER WITH THE EXTENSIVE EXPERIENCE OF OUR PERSONNEL, MEANS WE CAN GUARANTEE THE HIGHEST-QUALITY PERFORMANCE AND PROMPT AND RELIABLE DELIVERY.

RELIABILITY, INNOVATION AND CARE TO DETAILS: THE FOUNDATIONS OF OUR SUCCESS IN THE METAL PROCESSING MARKET.

LEADING COMPANIES CAN RELY ON OUR PRECISION, CUSTOMER CARE AND ON-TIME DELIVERY.

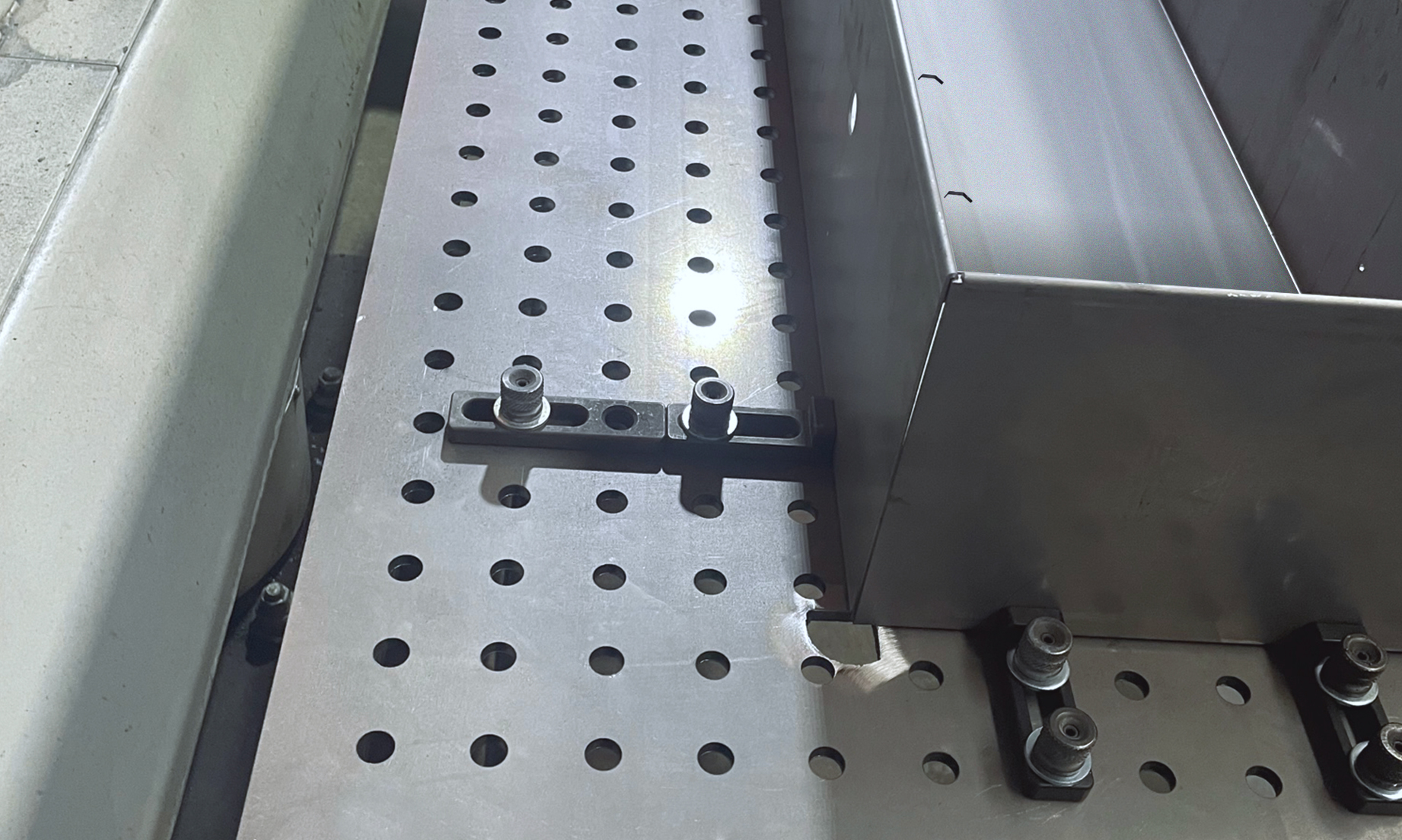

Precision welding is our flagship. We constantly invest in new robotic welding systems, welding certification and operator training. All of our operators hold a welding license issued by RINA Services.

OUR PRODUCTION

With our highly specialised team we can offer solutions tailored to meet the specific needs of our customers.

EXPERIENCE, INNOVATIVE MACHINERY AND HIGHLY-QUALIFIED PERSONNEL: HIGHEST QUALITY GUARANTEED IN EVERY TYPE OF PROCESSING.

During our production processes we carefully check the dimensional and aesthetic requirements of the manufactured items, so as to verify full compliance with customer specifications, drawings and expectations.